Mathematics of Metal Forming

Metal forming is the shaping of metal. Examples from manufacturing include rolling metal to create thin sheets and stamping flat sheets of metal to form car body panels. Ed BrambleyLink opens in a new window has been awarded a UKRI Future Leaders FellowshipLink opens in a new window to investigate how mathematics can lead to smarter metal forming in order to create new products, to reduce scrap, to compensate for more variable materials (e.g. recycled metals), to reduce costs, and to reduce energy usage.

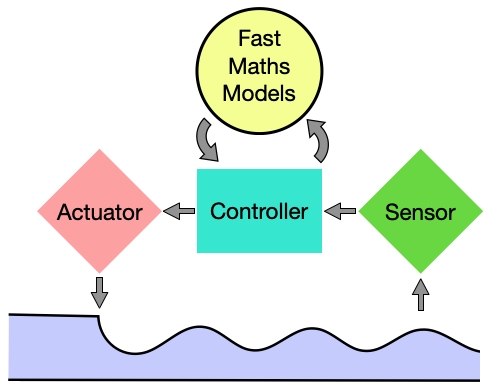

With current 21st century technology most people might expect smart computer-controlled metal forming processes, in which sensors would be used to monitor the metal workpiece during the forming process and actuators would adapt the process to correct any problems so as to obtain the desired end result. However, to find the best actions to take, the controller needs a theoretical model to predict the effect of different actions. The current state of the art is to use large-scale computer simulations (usually with finite-element methodsLink opens in a new window) in advance, as part of the development process or later in diagnosing problems, and then to use simple controllers (such as PID controllersLink opens in a new window) to blindly follow the pre-prescribed forming procedure. Computer simulations that take days to complete are too slow for use in real-time control.

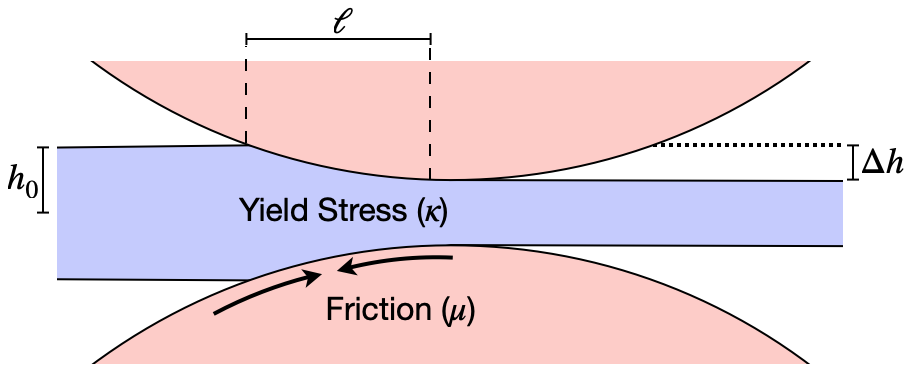

Brambley plans to study equations derived from continuum solid mechanicsLink opens in a new window and plasticityLink opens in a new window. This poses the problem as a system of Partial Differential Equations (PDEsLink opens in a new window), which can be approximately solved numerically by large computers using finite-element methods. However, instead, Brambley intends to use techniques of applied mathematics, such as making use of symmetry, or small parameters such as thin sheets, small deformations, and so on, Brambley hopes to create predictive theoretical models for industrial metal forming. New modelling techniques could give a substantial improvement, bespoke simplified models specific to each particular process.

This work involves collaboration between Brambley and his group of academic researchers, and Tata SteelLink opens in a new window and Primetals TechnologiesLink opens in a new window. Collaborating with industry helps ensure the new research is relevant to industry and provides new state-of-the-art techniques to industry once they have been developed in universities.

WMI Magazine staff

Published 12 October 2023

Controllers can be significantly improved with predictive models. The challenge is to obtain accurate models that can be evaluated quickly, on the fly. This is where mathematical modelling of solid mechanics and plasticity can help.

Asymptotics in cold rolling:

In the case where the ratio of lengths is small, asymptotic methods can be used to reduce the underlying equations to a more tractable form, as Ed explains hereLink opens in a new window.