Laser Micromachining Systems

Our laser machining facility consists of two Oxford Lasers systems: the E-Series (34 ns, 355 nm Nd:YAG) and the A-Series (15 ns, 532 nm Nd:YAG), both fitted with high-resolution CNC stages. These systems are capable of drilling, cutting and milling a wide variety of materials with high precision. Macro/micrometer scale features can be machined in metals, plastics, composites, wafers, diamond.

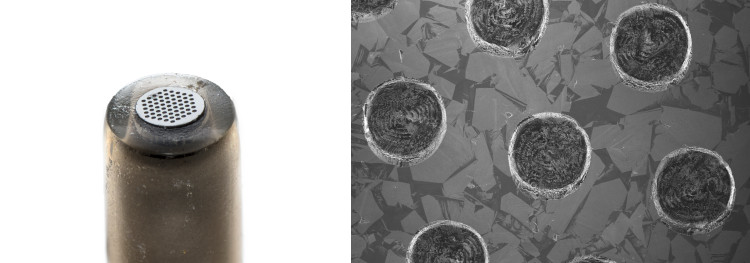

Above: Milling surface features for diamond based sensors. Machined pits are ca. 50 µm in diameter.

How Does it Work?

Laser machining is a non-contact, thermal process. Energy from the laser causes the removal of the target material through melting, vaporization and ablation enabling the machining of a wide range of materials including those that are difficult to machine by other methods e.g. diamond and composites. The material removal process is complex with many parameters that can modify the characteristics of the machined surface. Because the tool is not in contact with the surface during machining, sample damage and contamination is minimised.

Sample handling requirements:

The maximum sample size that can be accommodated is 200x200 mm (A-Series Laser) and 150x150 mm (E-Series Laser). Both lasers can physically accommodate samples up to 70 mm thick however the maximum machining depth varies depending on the material and laser. Typical machining depths are < 0.5 mm. The maximum thickness which we are able to cut for metals is 400 µm. Please contact us if you have questions about your sample suitability or for further information.

Warwick Capability:

Oxford Lasers E-Series; 34 ns, 355 nm Nd:YAG

Suitable for higher power applications such as cutting metals, diamond, SiC.

Oxford Lasers A-Series; 15 ns, 532 nm Nd:YAG

Low power applications, surface features, surface roughening, Kapton mask fabrication.

Members of the Diamond Research Group and Electrochemistry & Interfaces Group have a wealth of expertise in machining diamond for sensor applications.

Contact Us

If you are an external company or if you have questions about your samples suitability, lead times or machining requirements please Contact Us.

Booking Calendars

Trained users can access the Booking Calendars for the A-Series and E-Series.

Job Submission (Internal)

Internal users can submit jobs using the job submission form.

Applications

Sectioning wafers; cutting thin metal sheets; milling surface features; mask fabrication; machining complex geometries; surface roughening; materials that are difficult to machine by other methods.