Ultraviolet Photoelectron Spectroscopy

Ultraviolet photoelectron spectroscopy (UPS) is an analytical technique that can be used to obtain information about the electronic structure of conductive or semiconductive surfaces. An energetic profile can be built through measuring the photoelectron yield as a function of energy.

Applications:

Typical measurements include measuring the valence band or highest occupied molecular orbital of a material, the work function from the secondary electron cut-off and variations of these properties across a surface.

Typical samples include organic electronics, photovoltaics, perovskites, metal films and electronics.

How does it work?

How does it work?

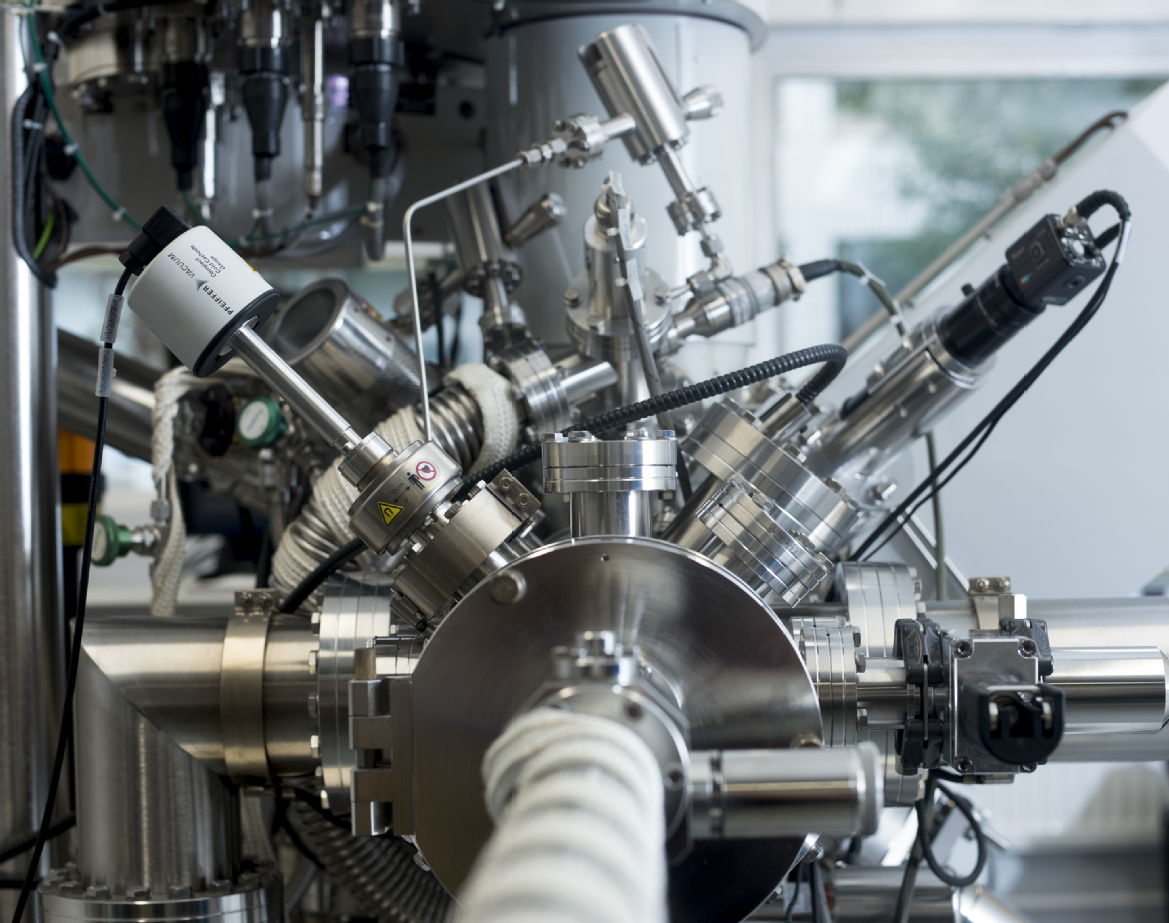

The sample is placed in an ultrahigh vacuum environment and exposed to a monochromatic ultraviolet photons with an energy of 21.2 eV or 40.8 eV. The incident photons cause the ejection of both valence and shallow core-level electrons from atoms close to the surface of the material. The energy profile of the emitted electrons allows you to determine the work function and ionisation potential of the material.

Sample handling requirements:

Sample size cannot exceed 15 mm in any lateral direction and can be powders. Height should not exceed 3 - 4 mm. Sample must be compatible with an ultra-high vacuum environment (<10-9 mbar). Please feel free to ask if you are unsure.

Complementary techniques:

XPS, TEM, XRD, SEM, EDX, AFM, PLD, STM

Warwick Capability:

Members of the Surface & Interface Group have a wealth of experience in UPS analysis.

Contact:

Claire Gerard: c dot gerard at warwick dot ac dot uk / 07385 145064

Contact:

Dr Ian Hancox, 024 76 150 380

email i dot hancox at warwick dot ac dot uk.

Dr Marc Walker, 024 76 151 776

email m dot walker at warwick dot ac dot uk.

Typical results format, and sample:

Status |

Availability |

|

Warwick collect/analyse data |

|

Warwick collect data |

|

Available to user with expertise/ contribution |

BOOK NOW |